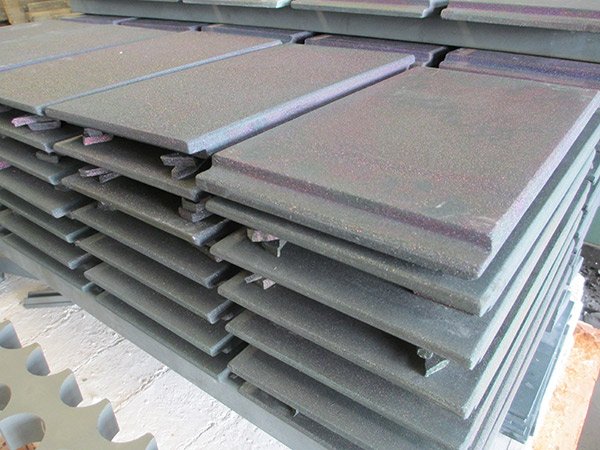

Sandwish ceramic sintering tray is a commonly used refractory kiln tool for firing magnetic materials and electronic ceramics. It has a high refractory temperature, but after firing, problems such as coating detachment and ceramic material adhesion may occur. Therefore, after using the burning plate for a period of time, it is necessary to sandblast and clean the burning plate with abrasives such as white fused alumina 80 mesh and 120 mesh.

There are several advantages to using white corundum sand for cleaning before spraying on sandwich firing plates:

1. Removing dirt and coating residues.

White corundum sand with 80-120 grit has strong abrasive properties. It can effectively remove dirt and coating residues on the surface of sandwich burnt plates. It ensures the adhesion and uniformity of the sprayed coating.

2. Improve surface roughness.

Using white corundum abrasive for cleaning can increase the surface roughness of sandwich burn plates. That is beneficial for adhesion after spraying paint and reduces the risk of coating peeling.

3. Enhance surface cleanliness.

White electro corundum sand cleaning can thoroughly remove dirt and impurities from the surface, ensuring a clean and tidy surface after spraying. In the meantime, it avoids peeling or cracking of the coating.

4. Improve surface adhesion.

By cleaning and removing oil and impurities from the surface, the adhesion of the coating on the sandwich burning board after spraying can be effectively improved, ensuring the stability and durability of the coating.

Overall, using white fused alumina sand to clean the surface of sandwich panels can provide a good preparation foundation for spraying coatings, ensuring the quality and performance of the coating, and extending the service life of sandwich panels.